Desoldering Pump versus Desoldering Iron

The plan for the midterm was to actually mount the product onto a perfboard. I did not want to solder the chip directly to the board because 1- We may want to build the final project off of this so changes may need to be made and 2- I may accidently melt the PIC while soldering. So I went to the junk bins and scavenged for a chip holder that would fit the PIC.

I found one on some old printer. I then began desoldering with the use of a soldering iron and desoldering pump.

Desoldering Pump

After 2.5 hours: I bent most of the pins, half the pins did not come out with the holder, and the pins that I was not able to reshove into their holes I either broke or lost. It was basically unusable.

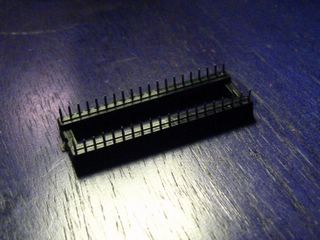

Chip Holder #1

My progress was not looking too good. I just wasted several hours on something that I could not use or salvage. I decided to rummage through the junk pile again and found another pin holder. I took that home and bought a desoldering iron from Radio Shack. It's a combo iron with the pump.

Desoldering Iron

Not only is the iron superior with the ease of use where I have the ability for one handed use versus needing four hands for the pump, I was able to get faster and cleaner results.

Chip Holder #2

The desoldering iron is definately worth the cost and worth saving the pain of more blisters on my thumb!

0 Comments:

Post a Comment

<< Home